- Home

- Products

- Greases & Gels

- High Speed Greases

High Speed Greases

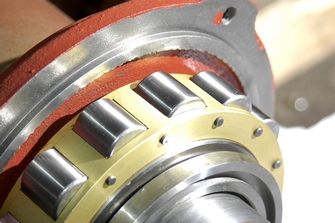

It is important to use a specialist high speed grease in fan bearings and other high-speed bearings. This is the best practice due to the high rotational speed of these bearings.

The problem is that the viscosity of the base oil used in a multi service grease is typically 150 or 220 cSt at 40°C. For the same load (torque) on the bearing, as the rotational speed increases the viscosity should decrease. The higher viscosity base oil of a multi service grease could lead to overheating, premature degradation of the grease and possible damage to the bearing. Bearing manufacturers offer a guide for maximum safe operating speeds.

The speed value (DN) for inner ring rotation, is the product of the ball bearing’s bore in millimetres and shaft speed in rpm.

Compare DN values with the manufacturer’s recommended value to determine type of lubrication and tolerance grade.

Speed factor = the internal diameter (ID) of the bearing in mm * the speed in rpm.

i.e. a 30 mm ID bearing with a rotational speed of 1000 rpm will have a speed factor of 30,000.

Usually oil lubrication is needed where speeds are very high (Speed factor is > 800,000) or where the temperature of the bearing is so great that there is a need for a cooling element from the oil.

The high speed grease range from IKV includes:

Our IKV-TRIBOSTAR EBK 22 which is a barium complex thickened fully synthetic grease designed specifically for high speed needle bearings and spindle bearings where a very high speed factor grease with resistance to cutting fluids and water ingress is required. Speed factor for this grease is Dn 1,000,000. IKV-TRIBOSTAR EBK 22 is a special grease based upon a synthetic oil having a low dynamic viscosity and excellent shear stability. The oil is thickened with a special Barium complex soap to form a soft, beige coloured grease.

IKV-TRIBOSTAR EBK 22 has a wide operating temperature range and has a very good resistance to aqueous solutions. This grease contains antioxidant and anti-wear additives, as well as a special anti-corrosion package.

The special properties of IKV-TRIBOSTAR EBK 22 make it a grease of exceptional performance and durability ideal for the lubrication of very high speed bearings throughout a wide operating temperature range. Typical applications include electric motors, machine tools, aeronautical applications, precision bearings. It is particularly recommended where there is a risk of water ingress, cutting fluid contamination or in the presence of condensation. Temperature range: -40 to 150°C.

IKV-TRIBOSTAR MBK 222 is a special barium complex soap thickened grease based upon a medium viscosity Mineral oil offering resistance to water washout, steam, acid and alkaline solutions where long life lubrication of components is required. IKV-TRIBOSTAR MBK 222 has excellent anti-wear & anti-corrosion properties with an excellent adherence to metal, high temperature resistance and mechanical stability. It is classified X-CEIB 2 according to the ISO 6743-9 (NF T 60-506) standard.

IKV-TRIBOSTAR MBK 222 grease is ideal for the lubrication of bearings, journals or heavily loaded articulations functioning in an aqueous environment. Applications include pumps, electric motors, washing machines, conveyor systems and transfer rollers. IKV-TRIBOSTAR MBK 222 is particularly well suited as a multi-purpose grease in the chemical and textile industries.

Temperature range: -25 to 150°C

IKV-PLEXSYN EL-2 CCI is a special low temperature lithium soap thickened grease which is used as a lubricant on automotive headrest applications. It is based upon a low viscosity synthetic hydrocarbon, polyalphaolefin (PAO) oil developed for the lubrication of components functioning at high speed and requiring low torque resistance and operation even at very low temperatures. It also has excellent anti-corrosion properties and mechanical stability. Its chemical inertness gives superior material compatibility with the majority of materials including the majority of plastics such as PC, ABS, POM and Pa.

IKV-PLEXSYN EL-2 CCI grease has been specifically developed for the lubrication of components where low temperature capability and a wide operating temperature range are required and where compatibility with a wide range of materials including plastics is required. The wide operating temperature range of IKV-PLEXSYN EL-2 CCI and especially its low temperature capability, make it ideal for applications on interior trim and similar applications within the automotive & electronics industries.

IKV-PLEXSYN EL-2 CCI is also suitable for the lubrication of mechanisms working at high speed where a low torque resistance is required especially when operating at low temperatures. It can also be used on copper alloy electrical contacts in an environment where plastic casings, housings or other plastic parts are present.

Temperature range: -25 to 150°C

IKV-PLEXSYN EL-2 TF is a lithium-soap thickened grease having a low viscosity PAO synthetic base-oil and PTFE solid lubricants. This grease was specially designed for the lubrication of parts working at high speed, that require a low resistance to torque at very low temperatures. It contains PTFE solid lubricants, which act as ‘back-up’ lubricants during boundary lubrication. This grease has a strong ability to eliminate noise, squeaking or juddering due to stick slip.

IKV-PLEXSYN EL-2 TF also possesses good anti-corrosion properties and mechanical stability. Its chemical inertness makes it compatible with the majority of seals and plastic materials, including polycarbonates. The material is used extensively for automotive applications where its operating temperature range and lubricating properties are ideally suited.

IKV-PLEXSYN EL-2 TF is also excellent for the lubrication of mechanisms working at high speed where the grease must have a very low resistance to torque.

Temperature range: -40 to 150°C.

IKV-PLEX 778A is a special lithium soap thickened grease based upon a synthetic polyalphaolefin (PAO) oil developed for the lubrication of components functioning at high speed and requiring low torque resistance and operation even at very low temperatures.

IKV-PLEXSYN EL-2 has excellent anti-corrosion properties and mechanical stability. It has excellent material compatibility with the majority of materials including plastics such as PC, ABS, POM and most sealing materials.

IKV-PLEXSYN EL-2 grease is ideal for the lubrication of copper alloy electrical contacts in an environment where plastic casings, housings or other plastic parts are present.

The wide operating temperature range of IKV-PLEXSYN EL-2 and especially it’s low temperature capability, make it ideal for applications in the automotive, electronics, control and instrumentation industries. IKV-PLEXSYN EL-2 is also suitable for the lubrication of mechanisms working at high speed where a low torque resistance is required especially when operating at low temperatures.

Temperature range: -40 to 150°C.

IKV-PLEXSYN EL-2 MP-TF is a special lithium-soap thickened grease having a low viscosity PAO synthetic base-oil and PTFE solid lubricants. This grease was specially designed for the lubrication of parts working at high speed, that require a low resistance to torque at very low temperatures. IKV-PLEXSYN EL-2 MP-TF contains PTFE solid lubricants, which act as ‘back-up’ lubricants during boundary lubrication. This grease has a strong ability to eliminate noise, squeaking or juddering due to stick slip.

IKV-PLEXSYN EL-2 MP-TF also possesses good anti-corrosion properties and mechanical stability. Its chemical inertness makes it compatible with the majority of elastomeric seals and plastic materials, including polycarbonates & POM.

The material is used extensively for automotive applications including interior trim applications where its operating temperature range and lubricating properties are ideally suited. IKV-PLEXSYN EL-2 MP-TF is also excellent for the lubrication of mechanisms working at high speed where the grease must have a very low resistance to torque.

Temperature range: -50 to 150°C.

IKV-PLEXSYN SEL-2 is a special, very low temperature lithium soap thickened grease based upon a low viscosity synthetic hydrocarbon, polyalphaolefin (PAO) oil developed for the lubrication of components functioning at high speed and requiring low torque resistance and operation even at very low temperatures.

IKV-PLEXSYN SEL-2 also has excellent anti-corrosion properties and mechanical stability. Its chemical inertness gives superior material compatibility with the majority of materials including the majority of plastics.

IKV-PLEXSYN SEL-2 grease has been specifically developed for the lubrication of components where low temperature capability and a wide operating temperature range are required and where compatibility with a wide range of materials including plastics is required.

The wide operating temperature range of IKV-PLEXSYN SEL-2 and especially its low temperature capability, make it ideal for applications on interior trim and similar applications within the automotive & electronics industries. IKV-PLEXSYN SEL-2 is also suitable for the lubrication of mechanisms working at high speed where a low torque resistance is required especially when operating at low temperatures. It can also be used on electrical contacts where plastic casings, housings or other plastic parts are present.

Temperature range: -55 to 150°C.

© 2026 IKV Tribology Ltd